2013/02/13

リスク対策ドットコム英語版>記事

- View developing business continuity strategies as a joint challenge with mutual benefits

- Share business continuity standards and policies

- Jointly conduct business continuity workshops to provide guidance in developing coordinated and integrated business continuity strategies and plans

- Share planning templates and tools

- Work together to develop contingency plans for what will happen when a disaster or significant operational disruption occurs, yours or theirs

- Conduct joint business continuity training sessions, exercises, and tests

- Keep the lines of communication open on an ongoing basis, not just after a problem occurs

●This article was translated into Japanese and published on magazine "Risk-taisaku.com" vol.34.

◆Profile Betty A. Kildow, FBCI, CBCP, has provided business continuity consulting services to a wide variety of businesses and organizations for more than twenty years. She is the author of “A Supply Chain Management Guide to Business Continuity” (2011), available in English and in Japanese: 「事業継続」のための サプライチェーン・マネジメント 実践マニュアル. Betty can be reached at BettyKildow@comcast.com or by phone at +001-765-483-9365.

リスク対策ドットコム英語版>記事の他の記事

- An ‘App’ for everything; But can Apps for Disaster save lives?

- Once upon a time in Fukushima

- UK experience of the Impact of Volcanic Eruptions

- BS25999 Certification Is No Guarantee of a Robust, Fit-for-purpose Business Continuity Capability

- A need to re-think the trade-off between continuity and productivity

おすすめ記事

-

海外危機管理マニュアルの作成が急務

海外に社員を送り出す企業にとって、緊急事態が発生した際の対応体制は必須。どんなに現地に慣れたベテランでも、自分の身を守り切れない事態は起き得ます。ましてや現在は安全保障上の国家対立が深まり、東アジアの緊張も高まっている時代。海外危機管理サービスを手がける安全サポートの有坂錬成代表取締役に、海外進出企業が取り組むべき対策を聞きました。

2026/02/05

-

リスク対策.PROライト会員用ダウンロードページ

リスク対策.PROライト会員はこちらのページから最新号をダウンロードできます。

2026/02/05

-

-

-

中澤・木村が斬る!今週のニュース解説

毎週火曜日(平日のみ)朝9時~、リスク対策.com編集長 中澤幸介と兵庫県立大学教授 木村玲欧氏(心理学・危機管理学)が今週注目のニュースを短く、わかりやすく解説します。

2026/02/03

-

-

-

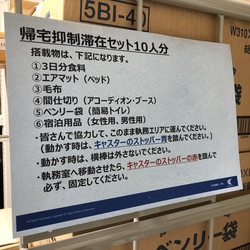

発災後をリアルに想定した大規模訓練に学ぶ

2026年1月14日、横浜市庁舎10階の災害対策本部運営室で、九都県市合同による大規模な図上訓練が行われた。市職員に加え、警察、自衛隊、海上保安庁、医療従事者、ライフライン事業者などが一堂に会し、市災害対策本部運営をシミュレーションした。

2026/01/26

-

-

![2022年下半期リスクマネジメント・BCP事例集[永久保存版]](https://risk.ismcdn.jp/mwimgs/8/2/160wm/img_8265ba4dd7d348cb1445778f13da5c6a149038.png)

※スパム投稿防止のためコメントは編集部の承認制となっておりますが、いただいたコメントは原則、すべて掲載いたします。

※個人情報は入力しないようご注意ください。

» パスワードをお忘れの方